Keeping it positive: BNSF hits milestones with Positive Train Control

By SUSAN GREEN

Staff Writer

BNSF achieved a safety milestone on Dec. 9, 2025, when the former Montana Rail Link (MRL) lines were fully implemented with positive train control (PTC) technology. In June, 36 miles were first put into service, followed by three more segments. Combined, that makes more than 216 miles of PTC protection on what is now the MRL subdivision on our Montana Division.

These milestones reflect ongoing advancements in this rail safety technology – one that has been center stage at BNSF for more than 20 years.

The system works in tandem with our other safety measures to prevent train-to-train collisions and derailments caused by track authority violations or excessive speed. PTC also prevents unauthorized train movement on track where employees are performing maintenance, as well as protects against movement of a train through a switch in the wrong position.

Today, BNSF has installed PTC on nearly 17,000 miles of track across our network, exceeding the nearly 15,000 miles that were mandated by the Federal Railroad Administration (FRA). That far exceeds the mandate and will protect even more of our people, trains and the communities in which we operate.

“BNSF made the decision early on to go above and beyond the regulation-required mandate to further provide safety overlay protection for our employees and the public on key routes across our network,” said Phil Mullen, BNSF director of Network Control Systems (NCS).

As for the newest PTC installation, he said the NCS and signal teams worked closely with our Montana Division leadership to coordinate all the necessary field and office work to achieve MRL PTC implementation — four months ahead of the FRA mandate.

“This is a major milestone for the BNSF PTC team and our biggest year of PTC implementation since 2017,” said Chris Matthews, director, NCS. “We started working with the MRL on PTC long before the reintegration into BNSF, and it’s great to see the team get this across the finish line ahead of schedule.”

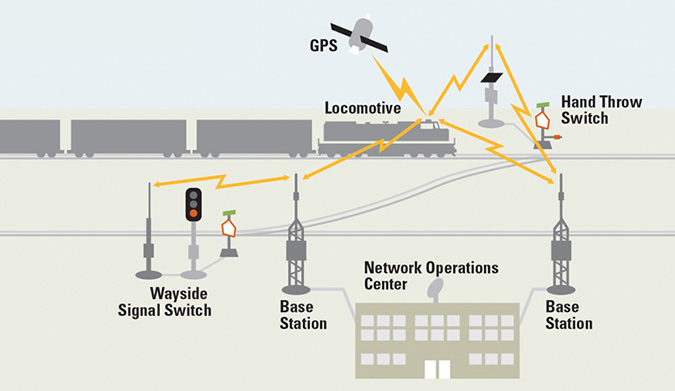

PTC uses the latest in digital wireless communication technology to transmit train-related information between locomotives, our Network Operations Center, and wayside switches and signals. The system works with GPS and takes in movement-related information like authority limits, speed limits and work zones through Wi-Fi, cellular and radio communication networks. The information is displayed on a screen inside the locomotive cab to help increase the crew’s situational awareness.

There are three main elements to the PTC system – the Onboard Locomotive System, the Wayside System and the Back Office Server. As a train moves, the onboard computer constantly calculates a warning and braking distance based on the train’s speed, speed limits, signals, switch positions, grade and work zones.

PTC gives an onboard warning if the train moves within the warning curve of a potential violation. If the locomotive engineer doesn’t respond before the train reaches the calculated braking distance, PTC will stop the train.

In addition to stopping trains before violations occur, PTC helps the locomotive engineer visualize the curvature, grade, signal and switch locations as well as grade crossings up to six miles ahead. This provides the engineer with advance information that can make train operations more efficient. An added benefit is the visual tool it provides to locomotive engineers as they learn new territories.

“PTC not only ensures the protection of our employees and the public, it also allows us to leverage the system for other benefits, like energy management integration, which supports our corporate fuel savings goals,” said Mullen. “The journey is never over as we continue to test and refine this highly complex system to support safe and efficient train operations.”